Tempered (Toughened) Glass

Tempered glass is made by heating and cooling a piece of standard glass in a tempering furnace. The glass, which must be pre-cut and edged before being put into the tempering furnace, is heated to approximately 1200°F and then cooled rapidly.

This process is also known as quenching. The quenching process leaves the glass hardened so that it is now approximately 4 to 5 times stronger, and therefore more resistant to breakage, than it was before the tempering process. If it does break, tempered glass shatters in small pieces that are less likely to cause injury or damage than non-tempered glass.

Laminated/Tempered Glass

Laminated glass is basically a glass sandwich. It is made of two or more plies of glass with a vinyl interlayer between (sandwiched, if you will, as in a car’s windshield). The glass will tend to stay together in case one is broken – thus qualifying as a safety glazing material.

The other key advantage to laminated glass is that it blocks 99 percent of the UV-light transmission, has sound reduction properties, it can be cut and its edges can be polished after laminating, and lead times are generally faster because most glass shops stock laminated glass. Certain thicker, multilayered forms of laminated glass can even qualify as burglar- and bullet-resistant glass.

Because laminated glass holds up to impact better than other types of glass, this is what is used in modern windshields. The sandwiched interlayer gives the glass structural integrity and keeps it from shattering apart like tempered glass might.

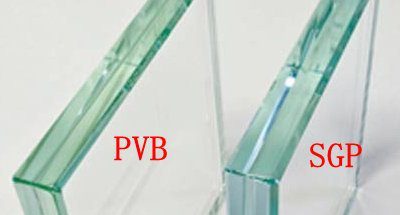

There are two type of lamination (see picture below). The main difference is “SGP” will stay standing when both sides are broken as compared to “PVB” it will fall down or break when both sides have become damaged.

Tempered vs Laminated:

So for strength and breakage-resistance, tempered glass often is the first consideration. For flexibility, UV-resistance, security and sound considerations, laminated glass is often the product of choice. Both are considered safety glazing materials and can be obtained in a variety of thicknesses and colors or tints. Both are easy to clean and maintain when installed properly.

Typically, laminated glass products are a slightly higher price than chamfered products of the same type and thickness. The optical clarity for both laminated and tempered glass are excellent in either product will provide many years of satisfactory service in your front door.